Material Requirement Planning (MRP)

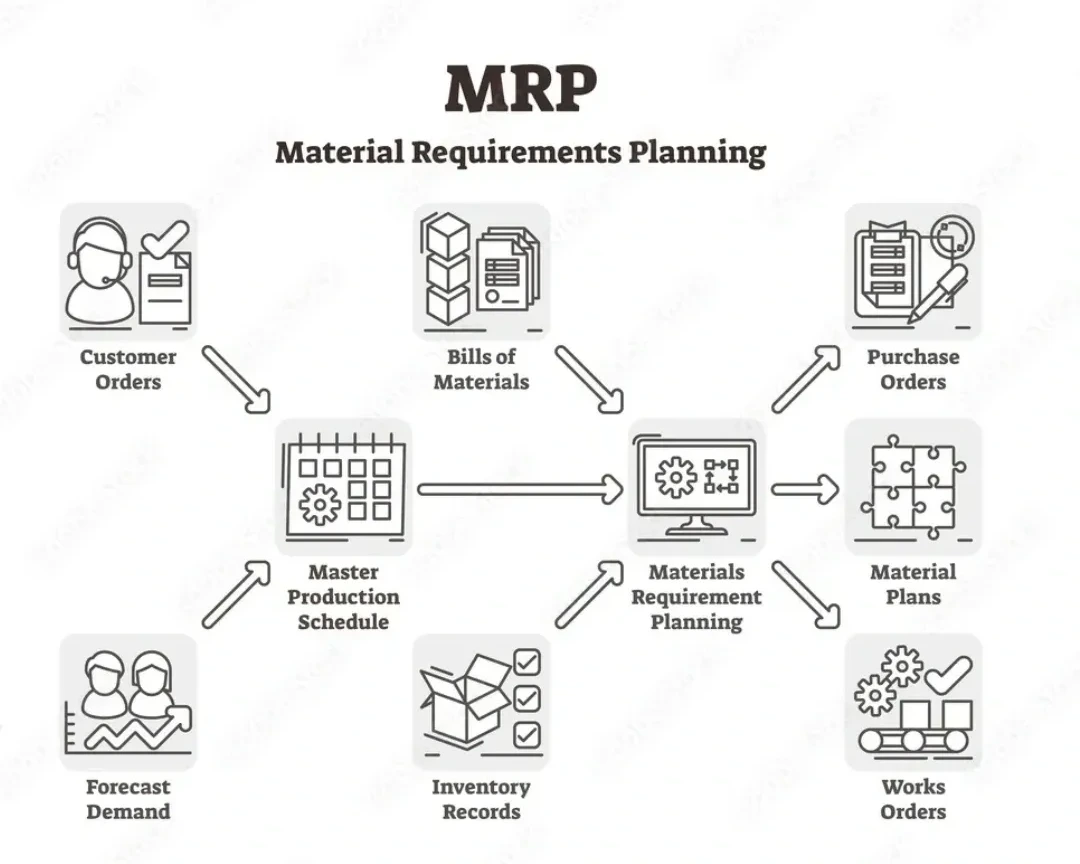

Material Requirement Planning (MRP) is a system that helps plan the materials needed for production.

It manages the entire material flow from tracking material origins and monitoring required components to generating purchase orders when inventory levels are insufficient.

Material Planning That Drives Productivity

Ensure the right materials are available at the right time.

The MRP software generates production plans for lower-level items by exploding the Bill of Materials (BOM). It can also pass the calculated requirements to an ERP system or other connected platforms for further processing.

Once the initial Master Production Schedule (MPS) is created, the advanced MRP system can display data through profile graphs and capacity usage graphs. Users can easily adjust the production schedule by clicking and dragging points on the graph for instant updates.

The MRP system enables manufacturers to evaluate how future demand changes will impact their production processes. When demand fluctuates—whether in quantity or delivery date—the system allows manufacturers to quickly assess whether production can still be completed on time.

The advanced planning software can generate accurate and practical Master Production Schedules (MPS) by considering pack-forward numbers, stock coverage targets, production setup requirements, minimum and maximum reorder quantities, reorder multiples, and product shelf life. Capacity can be defined by quantity, time, or weight using the MRP calendar, and it can be adjusted at any time. The available capacity then determines the amount of production that can be scheduled in each period.

Benefits of MRP Systems

Create optimized production schedules

and respond quickly to changes in demand or capacity, ensuring customer orders are fulfilled on time.

Improve operational efficiency

by reducing downtime and enhancing resource utilization, leading to smoother processes and higher output.

Integrate inventory data, production schedules, and resource allocation

to provide real-time visibility, enabling informed decision-making and improved production performance.

Optimize inventory levels

reduce waste, and enhance production workflows, resulting in higher efficiency and lower operational costs.

Enable real-time visibility

into production schedules, inventory status, and customer demand changes, allowing manufacturers to adapt quickly to market shifts.

Reduce inventory costs and minimize lead times

improving operational efficiency and strengthening pricing competitiveness or profit margins.