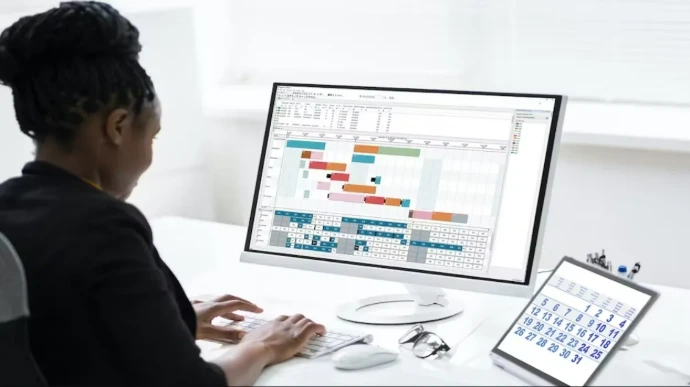

Opcenter Advance Planning and Scheduling

This software provides advanced production planning and scheduling by using capacity data, available resources, and various production constraints to create an optimized plan. It maximizes resource utilization and offers additional insights to support decision-making, enabling planners to quickly respond and adapt to changes in the production process.

Plan Smarter Produce Faster

Advanced tools to help you maximize capacity, reduce delays, and stay ahead.

Opcenter Advance Planning (AP)

This software is designed for medium- to long-term production capacity planning. It provides visibility into production items and required quantities under defined conditions (Master Production Schedule: MPS), along with detailed material requirements for manufacturing (Material Requirements Planning: MRP). It supports better decision-making and resource planning to ensure products are delivered on time.

Opcenter Advance Scheduling (AS)

This software optimizes production sequencing based on specific environments and available resources for short- to mid-term planning. It provides an accurate production sequence under defined conditions

such as prioritizing urgent items and minimizing changeover time while allowing real-time tracking and on-the-fly schedule adjustments. It also displays material requirements to identify potential shortages and compares actual production times against planned targets to evaluate overall production efficiency.

How an APS system can help?

Benefits of APS (Advanced Planning & Scheduling)

Improve production efficiency

with faster, more accurate workflows through optimized planning and sequencing.

Maximize resource utilization

by allocating machines, manpower, and materials effectively.

Reduce inventory and storage costs

by preventing overproduction and aligning output with actual demand.

Shorten production lead time

and minimize delivery delays with better scheduling control.

Minimize errors

and enable immediate adjustments when issues arise on the production floor.

Support future growth

by providing clear insights for capacity expansion and long-term planning.

Integration Customize

The software is designed to seamlessly integrate with leading Enterprise Resource Planning (ERP) systems such as Oracle, SAP, Microsoft Dynamics AX, and more. It also supports full customization, allowing organizations to adapt the system to their specific processes and operational needs.